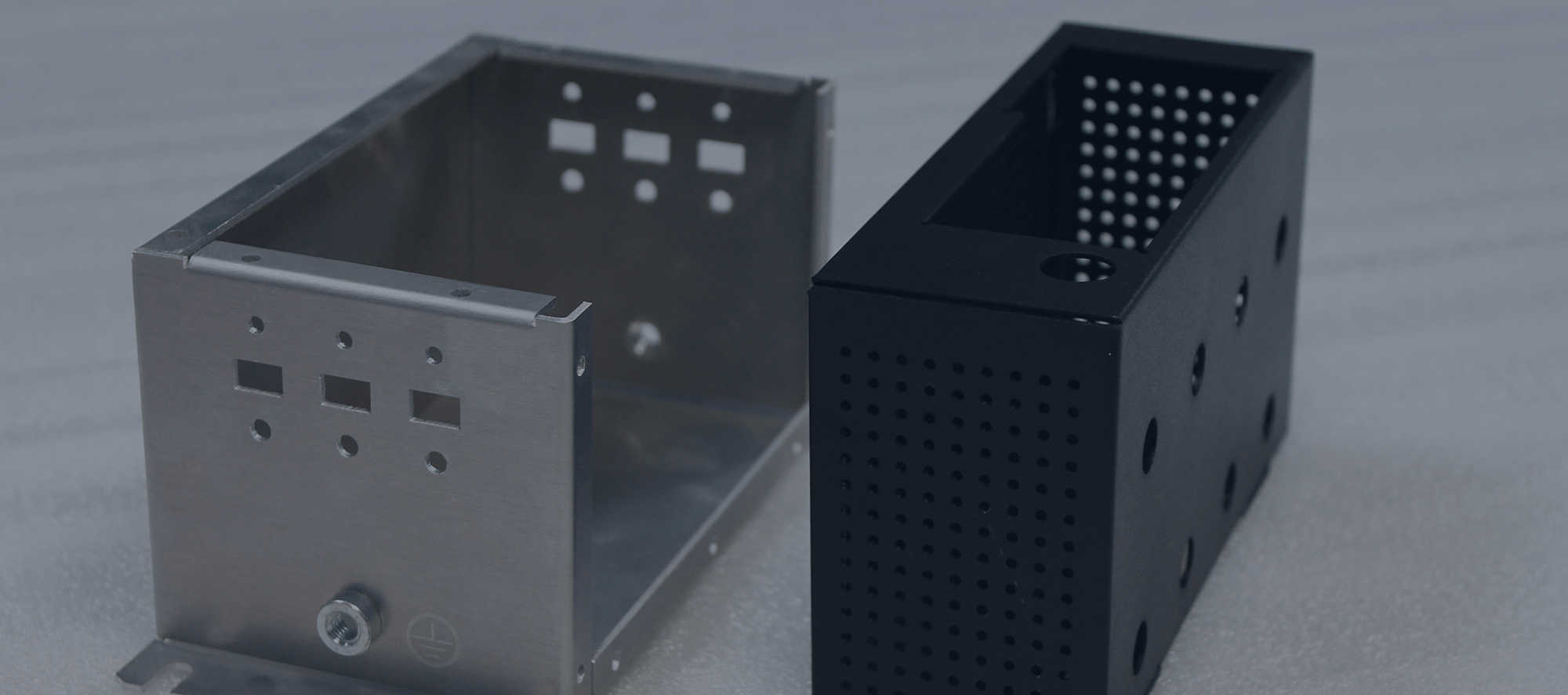

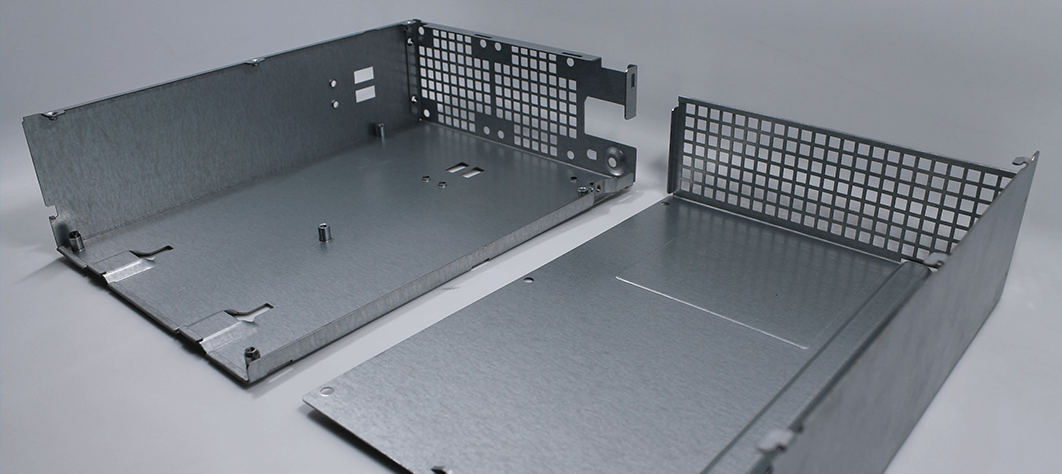

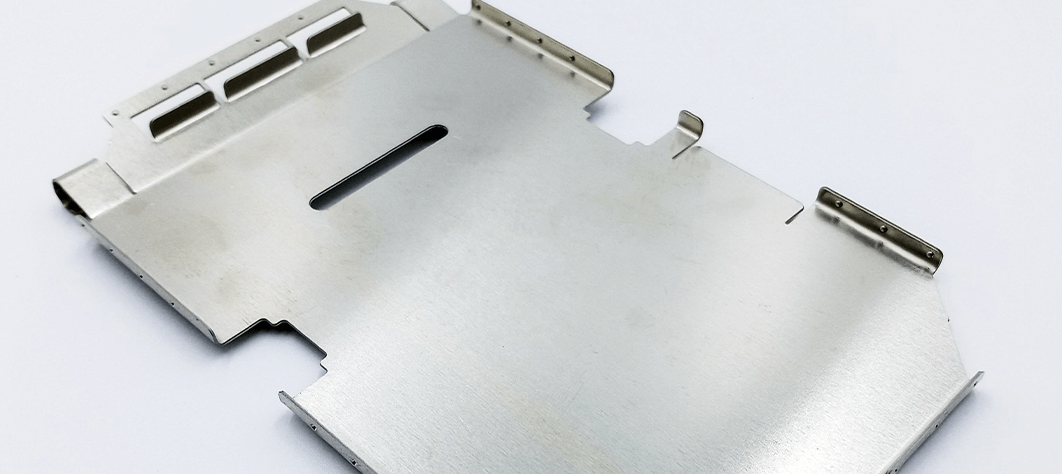

At Rebornwell, we specialize in high-accuracy sheet metal fabrication for industries demanding tight tolerances and repeatable quality. Our capabilities combine advanced technology with artisan craftsmanship to transform raw metal into precision components.

Key Processes & Advantages:

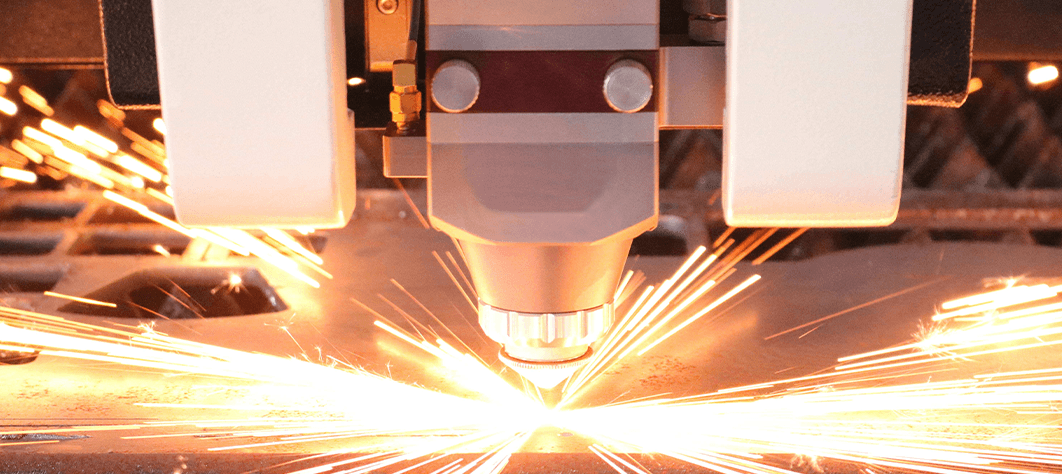

✔ Laser Cutting - Fiber laser systems handle stainless steel, aluminum, and copper (0.3-2mm thickness) with ±0.1mm precision

✔ CNC Punching - Multi-tool setups for complex geometries and high-volume production

✔ Bending/Forming - CNC Bending Machine achieve angles within ±0.5° tolerance

✔ Welding & Finishing - TIG/MIG welding with post-process deburring and surface treatment

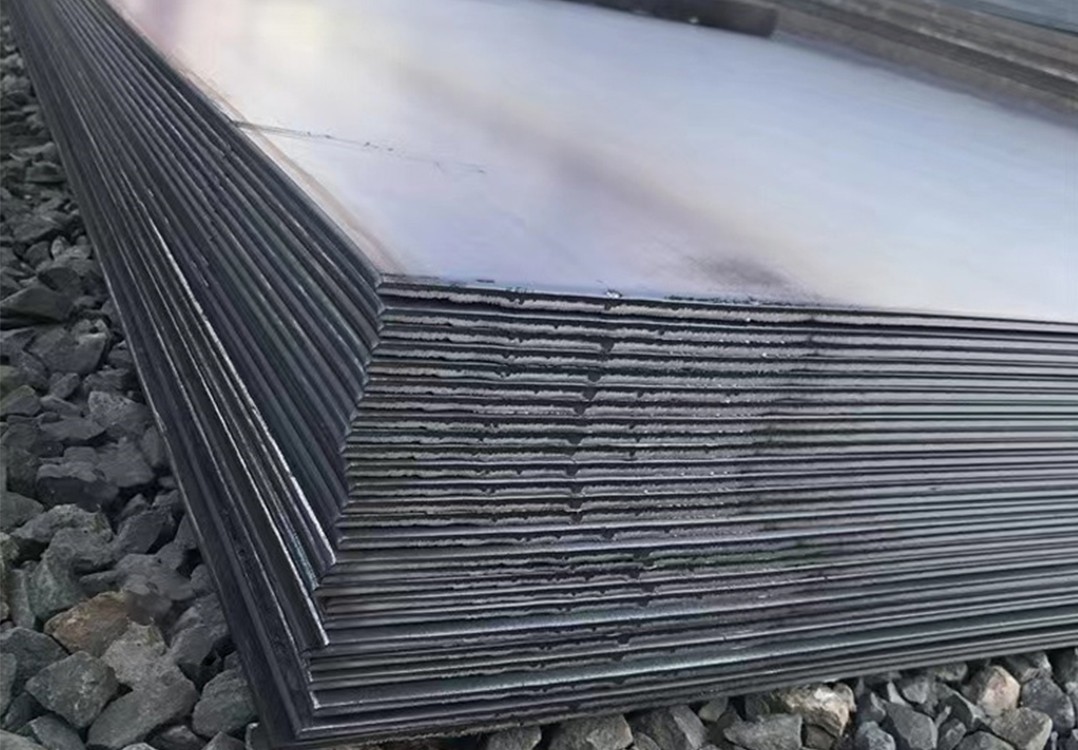

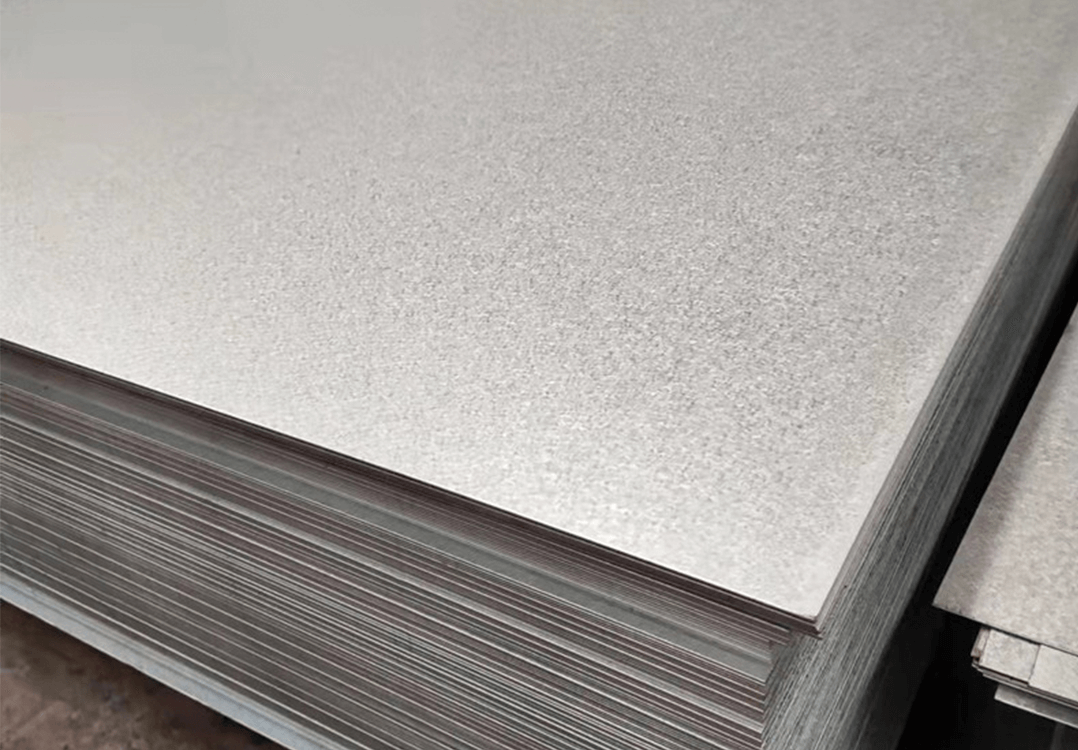

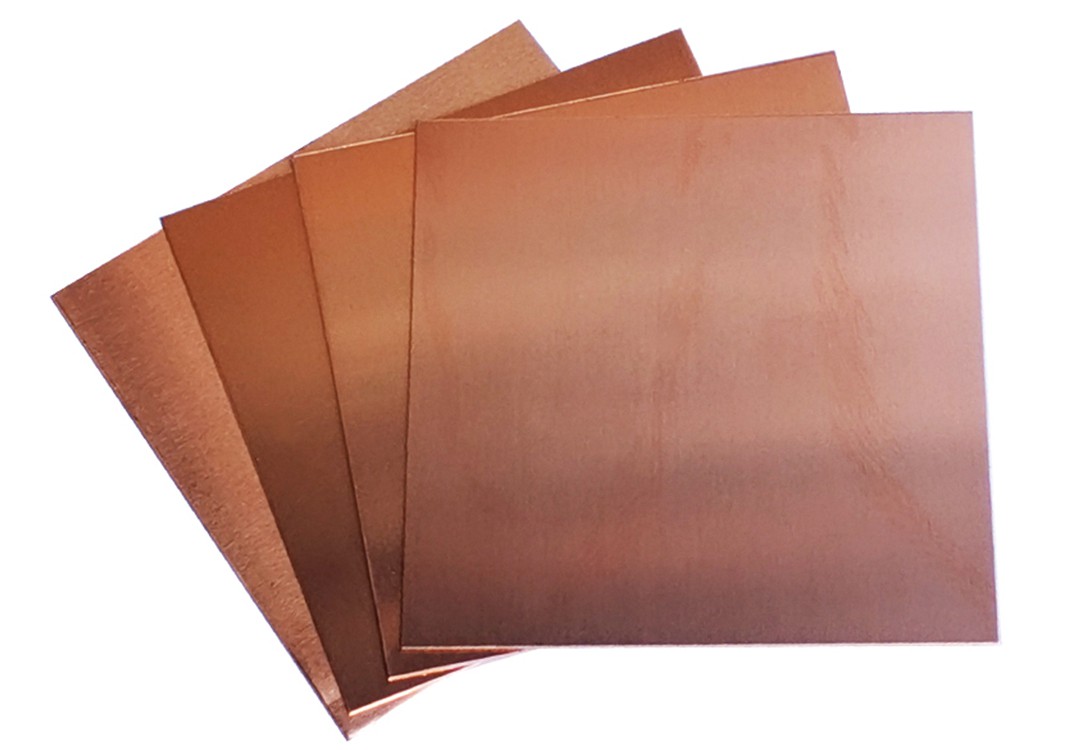

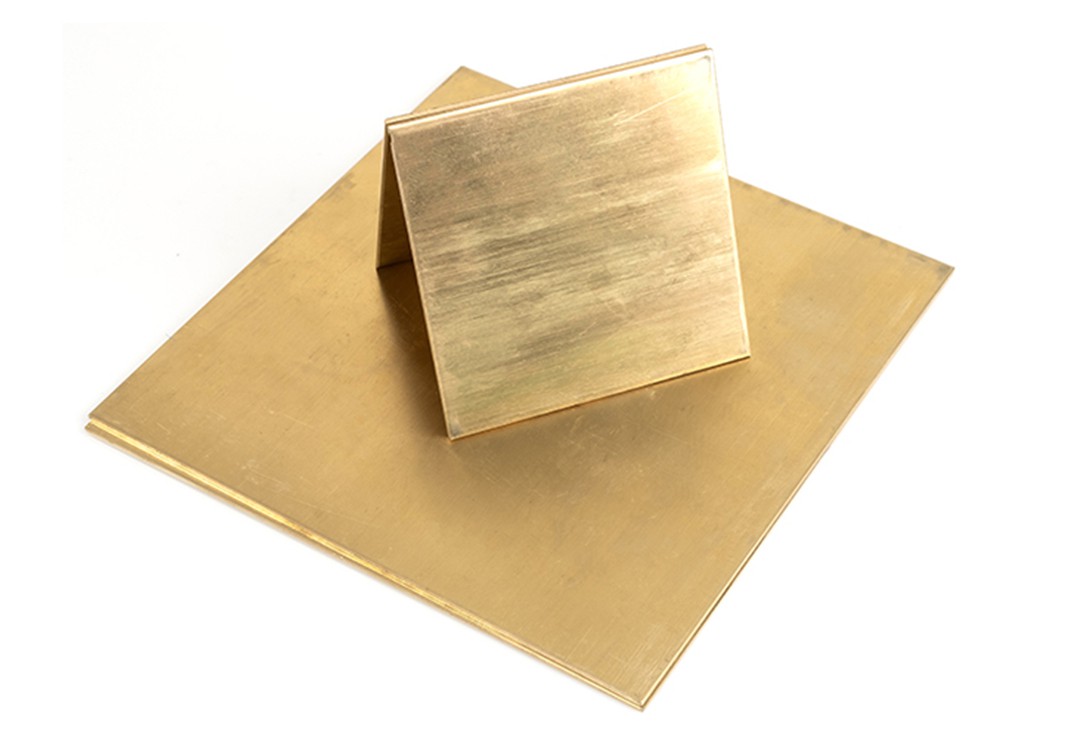

Materials Expertise:

· Stainless Steel (304/316)

· Aluminum (5052, 6061)

· Carbon Steel

· Copper/Brass

Quality Assurance:

· First-article inspection with CMM verification

· In-process dimensional checks

· Custom packaging to prevent transit damage

From prototype to production – we deliver sheet metal solutions engineered for performance