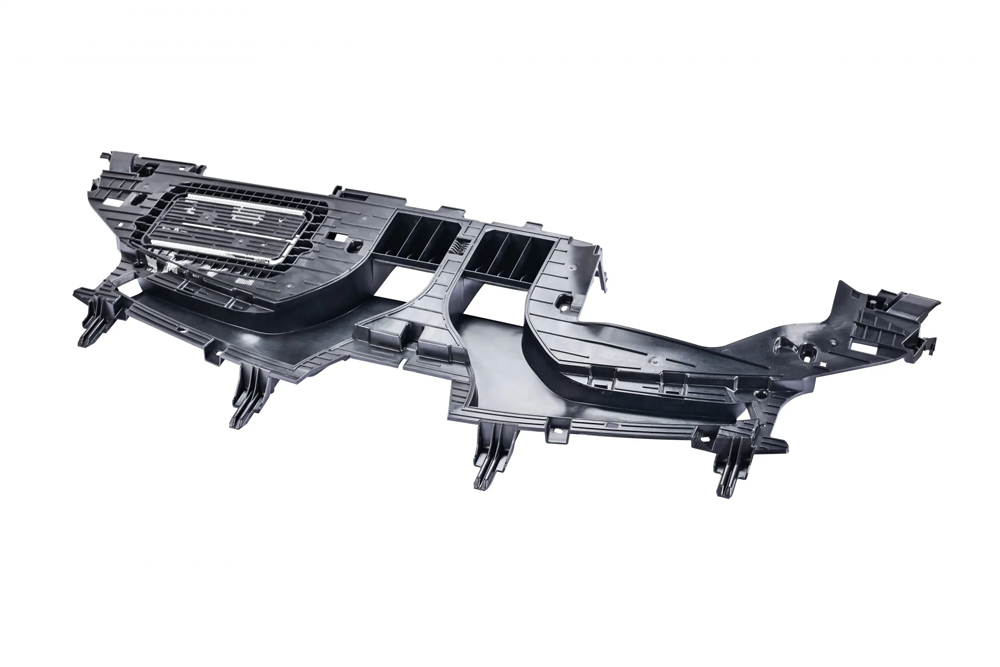

Precision Injection Molding Services

Fast | Precise | Cost-Effective

We specialize in high-quality plastic injection molding with quick turnaround and exceptional precision. There is no limit on the order quantity. Our optimized process delivers molded parts with:

✔ Tight Tolerances (±0.02mm)

✔ Fast Cycles (Prototypes in 7-10 days, production in 15-20 days)

✔ Material Expertise (100+ engineering-grade resins available)

✔ Complete Solutions (From mold design to post-processing)