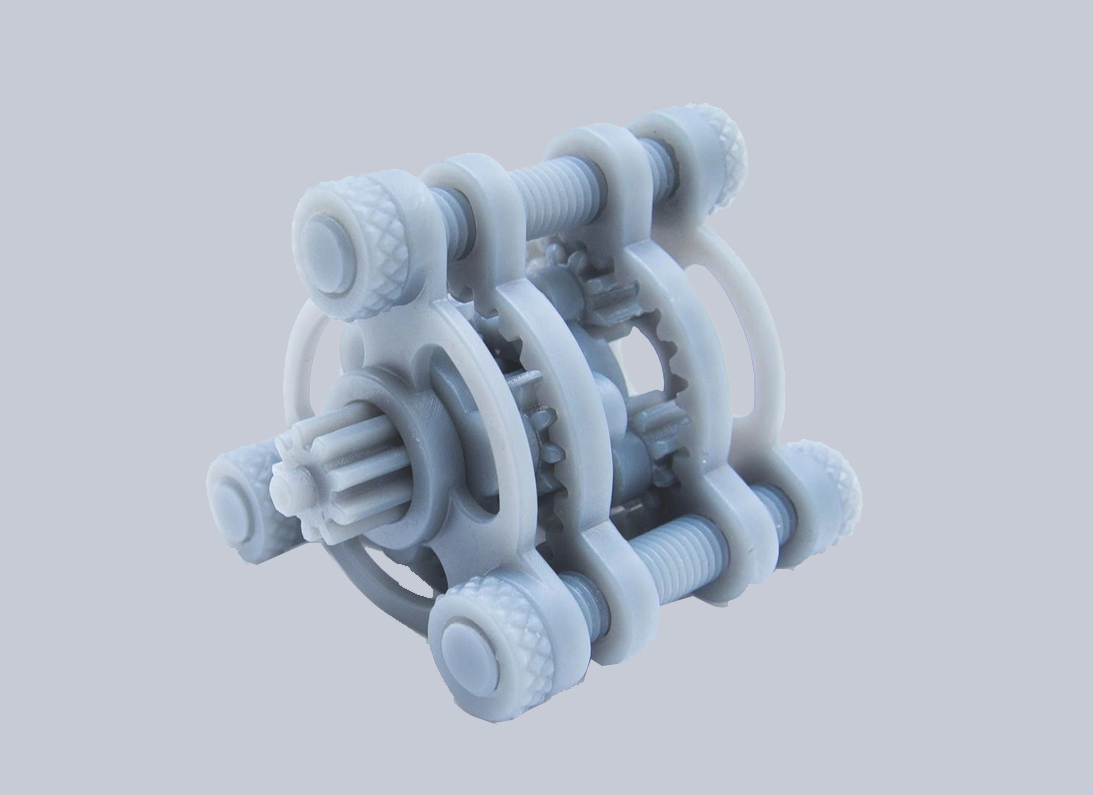

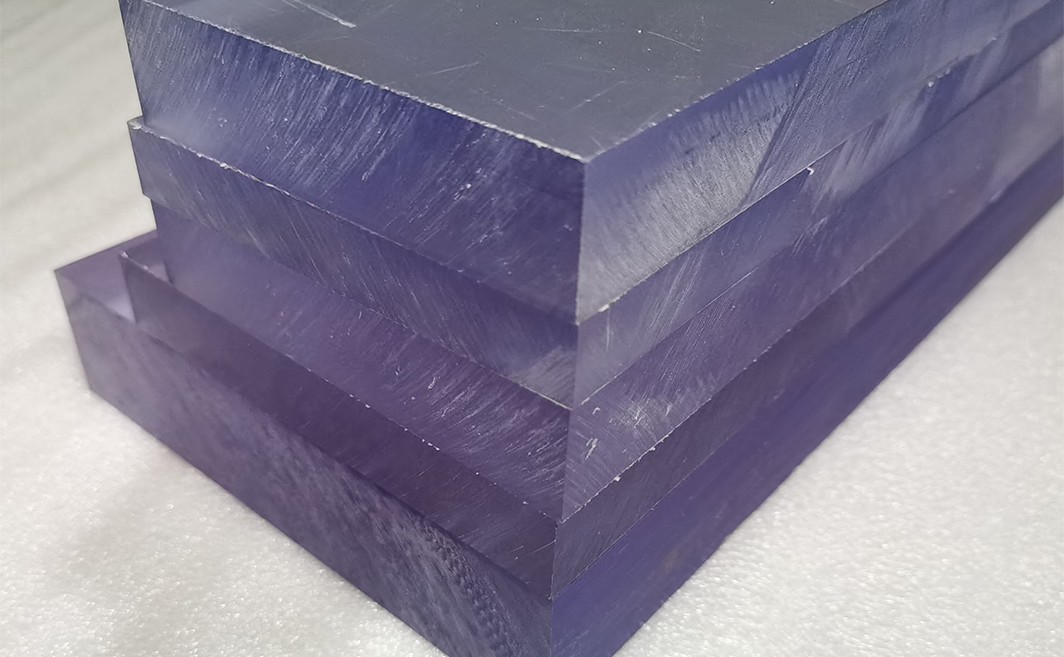

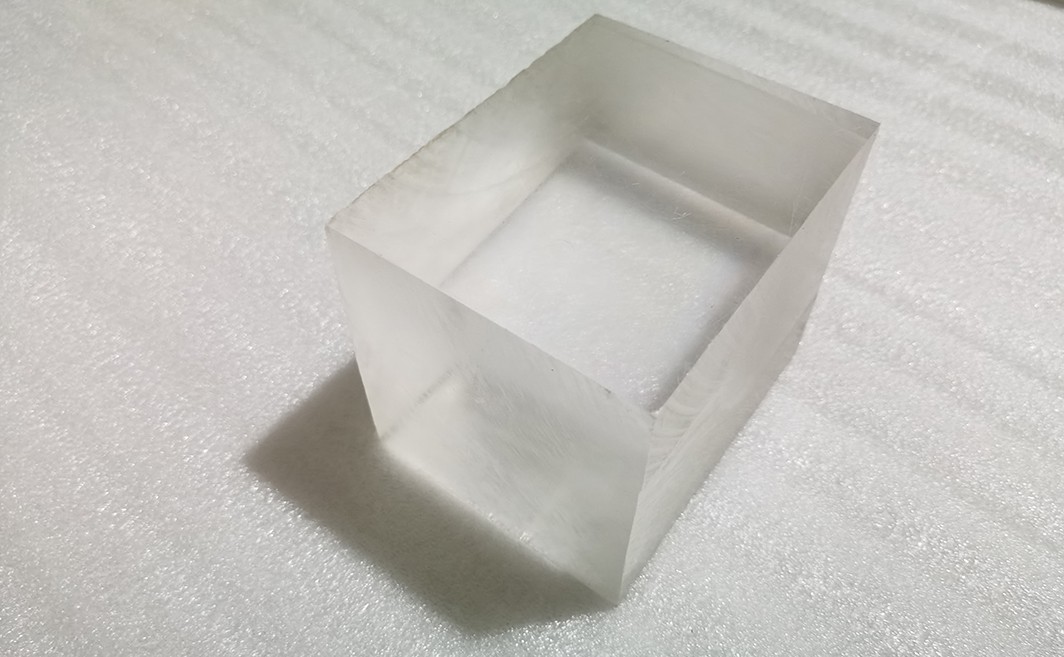

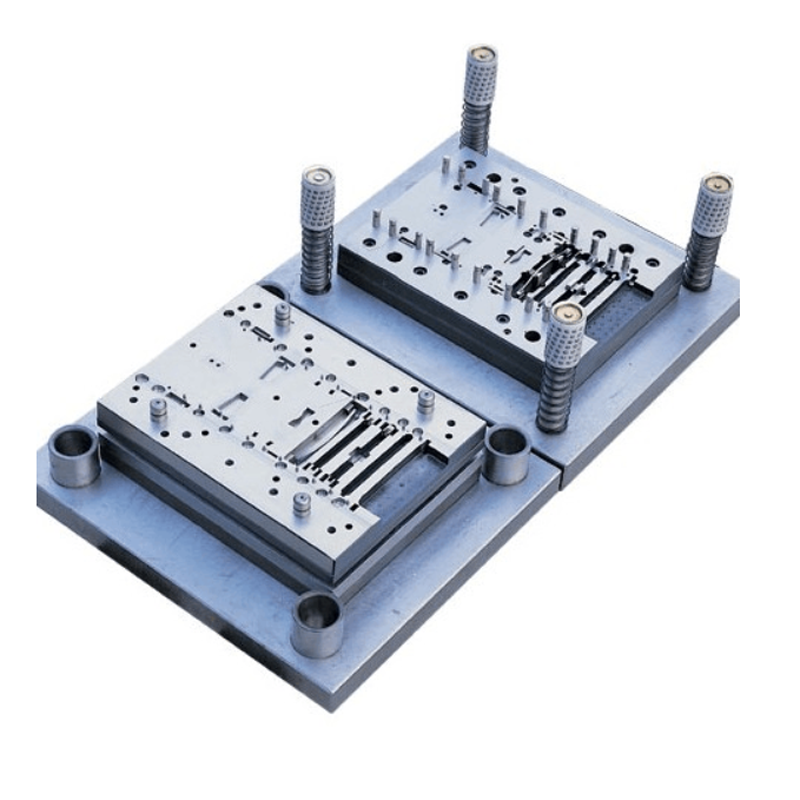

Rapid Prototyping at Rebornwell – From Concept to Reality in Days

Speed Without Compromise

Our rapid prototyping service delivers functional prototypes within 3-7working days, accelerating your product development cycle while maintaining precision standards.

Rebornwell has more than 10 years of rapid prototyping experience, cooperated with more than 20 international well-known enterprises, completed more than 1200 projects and manufactured 20,000+ prototypes, with rich experience in prototype manufacturing, Rebornwell is a prototype expert you can always trust.